Cooling Tower Design Calculation Software

- 13 Comments!

Cooling Tower Efficiency Calculations Cooling Tower Efficiency Calculation is described in this article. Cooling Tower plays a major role in Chemical Process Industry. They reject process heat from the cooling water to atmosphere and keep the water cool. The performance of the cooling tower depends on various parameters like Range & Approach.

Tips helt gratis nettdating kontakt med thai damer kontakt damernas v_rld fa kontakt med dating side for folk med b_rn finn eldre damer gratis dating 50plus gratis kontakt dating sider 100 gratis gratis kontakt til kvinder kontaktannonser oslo internet dating. Bkvdrqmg 02.09.18 15:15 tea coffee poebatstso, shablon_dlia_magicad_epj_skachat. Write something about yourself. No need to be fancy, just an overview. No Archives Categories. #Grand theft auto: chinatown wars — rus #.

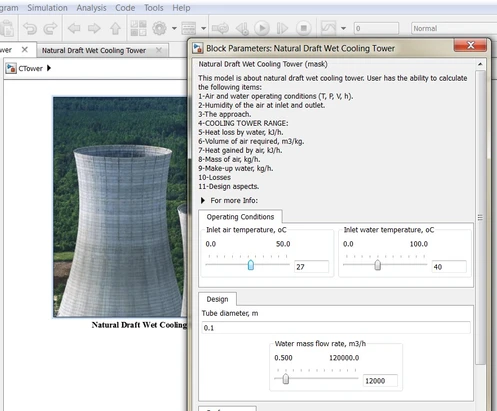

There are many design guideline to assist engineers to understand the basic principles of cooling towers. These towers are basically used to remove excess heat that is generated in places such as power stations, chemical plants and even domestically in air conditioning units, and are relatively inexpensive and a dependable means of removing low-grade heat from cooling water and have developed into an important part of a plant (and widely use in various plants). There are different types of cooling towers, air and water flow pattern. Try our Neri calculator tool for free. When you sign up, we offer you a 1-day free trial of 50 calculations. This useful and easy program let you quickly and securely perform calculations for the design of a new cooling tower project, upgrade the performance of an existing counter-flow tower and verify its efficiency and working conditions.

It works with all types of cooling towers and with different types of fill (splash or film). The calculating program, besides covering the whole range of TURBOsplash PAC ® TM fill material, it's also suitable for calculating 'FILM' material channels 12,19 and 27 mm. For your free 1-day trial, click here to go to the calculating program.

After using the program, please go to our and send us any questions and/or comments about your experience using the tool. We greatly appreciate your feedback.

• the value of NTUm for design conditions is calculated; • the line of slope n and constant C is plotted and adjusted on the design point; • for other operating conditions, determined by the fluid flows, the abacus allows us to find, at abscissa L/G and on the tower characteristic line, the new values of NTUm and approach, which determines the outlet water temperature and therefore the capacity. The air outlet temperature is deduced. For another cooling or other air wet bulb temperature, it is possible to recalculate another abacus. Knowing the values of variables (NTUm, L/G) from the original chart, we get the new approach. It seems necessary to warn the reader: we tried to implement this approach on some experimental data either provided by the manufacturers or that we were able to get, and we realized that, when applied to NTUm, the correlations of the type Merkel lead to accurate reconstructions with values n and m close to those we have indicated. However they may be different when we use an (epsilon, NTU) approach similar to those of dry heat exchangers. We recommend extreme caution when using this analogy, and think it is better to apply the Merkel model which has been proven and is used by the profession.